Engine Oil Analysis

Engine Oil Analysis Basics

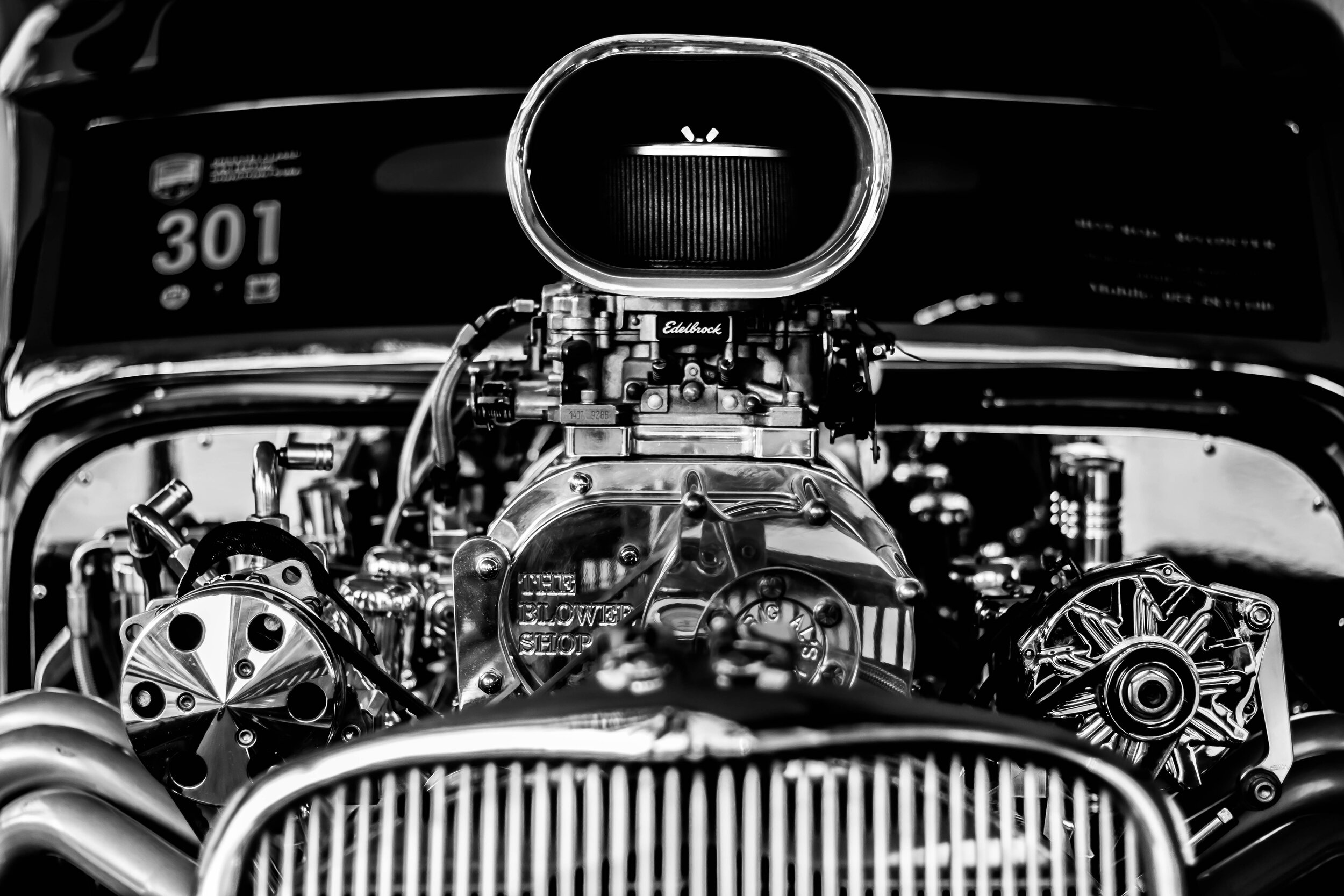

Keep the rods in the block

Engines run hard, hot and have erratic duty cycles. From idling in cold to running hard in the summer heat your engine has a hard life. By keeping an eye on the oil you can help assure its ready to perform.

Key Issues

Dirt: Dirt entry into an engine is certain death. The rings and cylinders will not tolerate any abrasive material.

Coolant: Antifreeze (Glycol) is critical for cooling but it can migrate into the engine through bad head gaskets and other culprits. Once into your engine the Antifreeze will start to attack soft metals such as lead, tin and copper. This can lead to bearing failure quickly.

Fuel: Fuel is critical for going places but it to can migrate into the engine through bad injectors and other culprits. Once into your engine the fuel will lower you oils viscosity and not allow it to lubricate the engine properly. This can lead to bearing and or cylinder failure quickly.

Viscosity: Making sure you have the right oil type and viscosity for your specific application is crucial for engines proper operation.

Oil Life: High temperature causes oil to degrade fast. Engine oil has a finite life and by monitoring the Oxidation and Nitration we can help you schedule oil changes to save oil and maximize the lubricants life.

Bearing Failures: A rod bearing failure can destroy your block and add thousands of dollars to a rebuild. By monitoring the oils lead content we can identify bearing failures early. With a combination of oil and filter analysis we can help you keep your rods in the block for the life of the engine.

Recommended Testing

Wear Metals by ASTM D5185

Additives by ASTM D5185

Viscosity at 100C by ASTM D445

Oxidation by ASTM E2412

Nitration by ASTM E2412

Soot by ASTM E2412

With Cool, Clean, Dry oil your equipment can provide many years of reliable service. We can help your team set realistic goals for cleanliness and work together to achieve them.

Keep the inside of your engine as clean as the outside