Hydraulic Systems

Hydraulic Oil Analysis

Whether its a plant or a piece of Mobil equipment not much moves without hydraulics. By using Oil Analysis Lab Inc’s hydraulic oil analysis program you can maximize oil life and predict failures in the system. Hydraulic Fluid Analysis gives you exact measurements on key parameters such as metals, additives, viscosity, acid content, water and particulate.

Key Issues

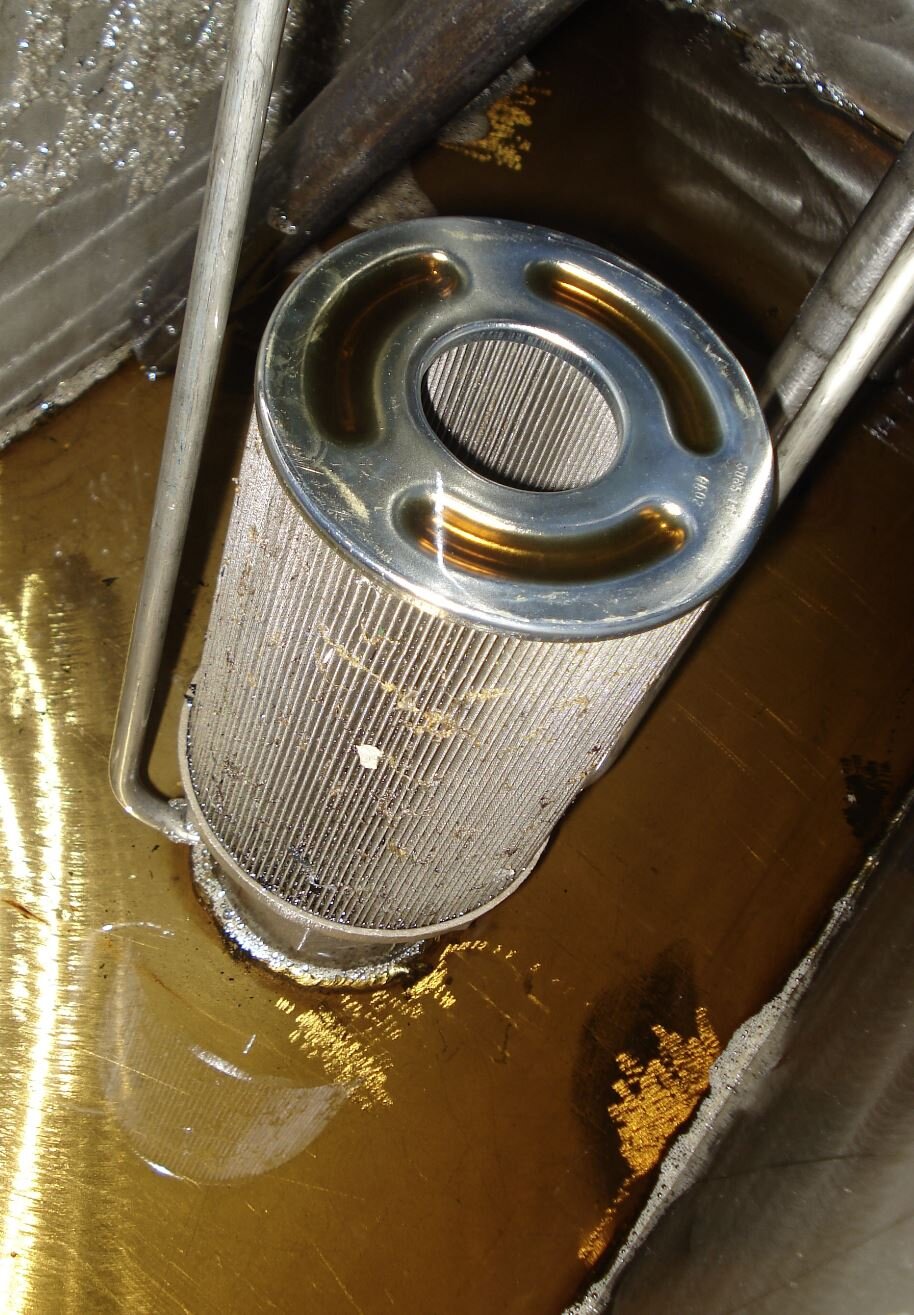

Varnish: Varnish can form due excessive temperature, long oil drains and throttling valves. Once it starts to form it can wreak havoc on servo valves and plug filters.

Hard Particulate: Particles such as Dirt and Metal can also wreak havoc on valves and damage the component.

Viscosity: Making sure you have the right oil type and viscosity for your specific application is crucial for proper operation, response time and safety.

Oil Life: Rapid Cycles times, high pressure, high temperature and tight tolerances all cause oil to degrade fast. Hydraulic fluid has a finite life and my monitoring the acid content and particulate we can help you schedule oil changes to save oil and maximize the lubricants life.

Pump Failures: A failing hydraulic pump makes for slow production and can lead to unsafe work conditions. By keeping an eye on your hydraulic systems copper and iron content you can predict pump failures ahead of time and plan maintenance around that.

Recommended Testing

Wear Metals by ASTM D5185

Additives by ASTM D5185

Viscosity at 100C by ASTM D445

Particle Count by ISO 11171

Water Content by ASTM D6304

Acid Number by ASTM D664

With Cool, Clean, Dry oil your equipment can provide many years of reliable service. We can help your team set realistic goals for cleanliness and work together to achieve them.

Oil Analysis looks inside your hydraulic system to give you insight into the component